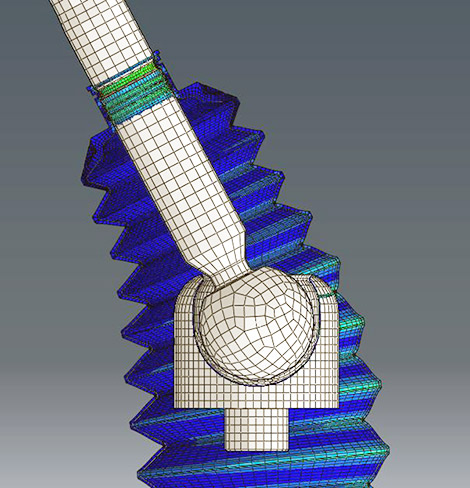

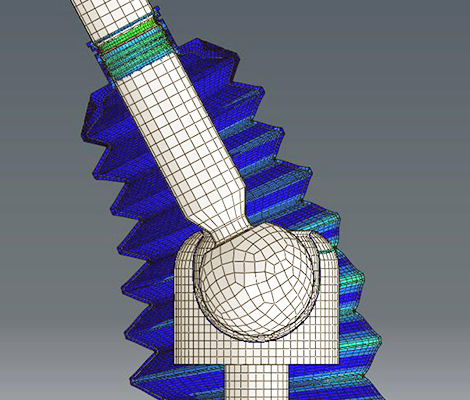

Another important chapter of MPE experience is represented by knowledge on tools. All three technologies – molding, traditional blow molding and injection-blow molding (Pressblow molding) – are in-house conceived, designed and developed by our Technical Department.

For tool’s construction MPE is assisted by a range of selected suppliers, both Italian and foreign. This allows to ensure to the end customer innovative solutions along with competitiveness.

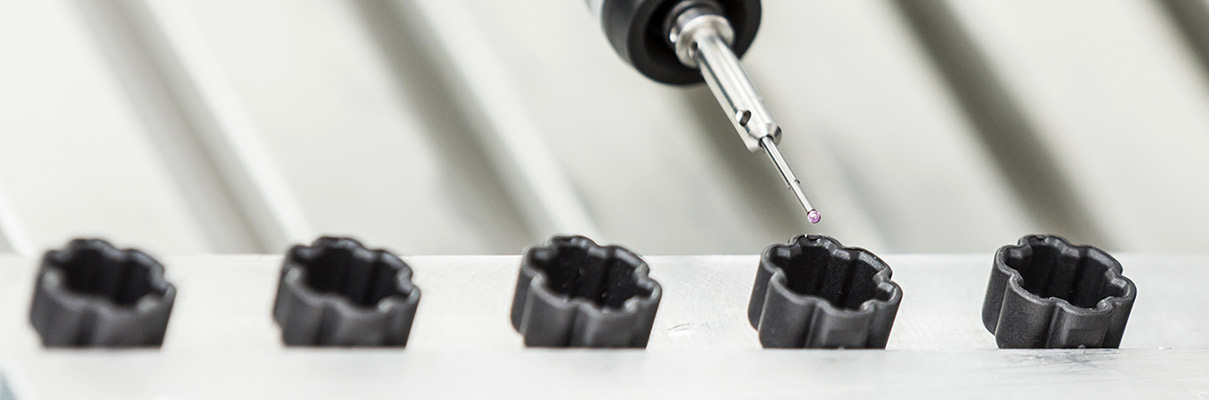

Our maintenance/service workshop ensure all tooling and equipment to always perform at the highest quality standard.