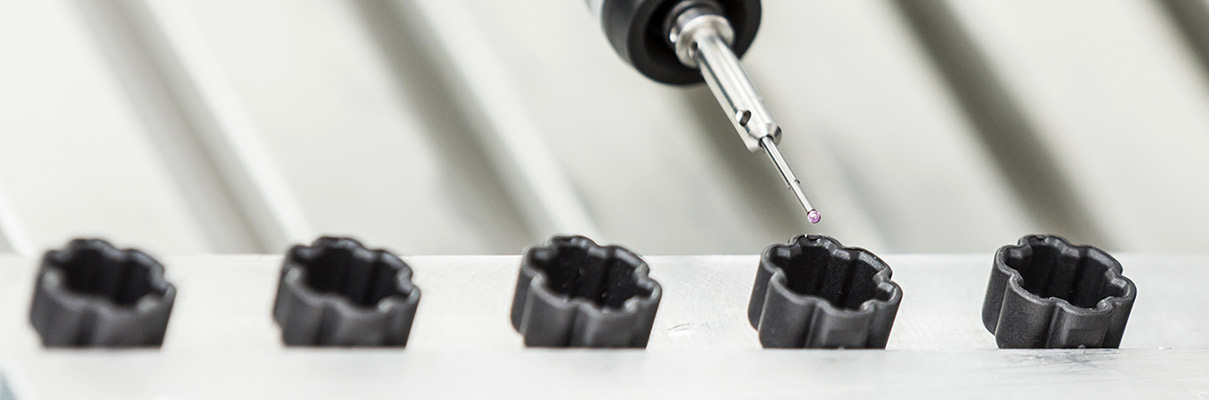

Our central Quality Laboratory located in Mathi (ITA) is able to perform accurate controls and precise dimensional measurements, using some of the most sophisticated tools.

Our metrology equipment includes some very peculiar machines as:

- Three-dimensional machine for contact measurements CMM – Coordinate Measuring Machine

- Measuring machine with optical axes of motion

- Machine continuous scanning

Alongside the technological tools also operates the experience gained in over 40 years of work that leads MPE to fulfill the most common protocols for the automotive industry as VDA and PPAP, as well as more specific customers related norms.

TEST

MPE is able to provide its Customers with a full service support also in the validation phase, especially for the steering gears sector. A specially equipped climatic chamber can perform salt or sand spray durability tests from -40° to + 150°C, simulating the different climatic and agents conditions the final product will have to endure in its whole lifetime.

The dynamometer is another key component for the validation of our products. MPE currently uses a machine capable of measuring forces up to 20 kN in a controlled environment, thanks to a climatic chamber connected to the dynamometer itself.

We also perform raw material analysis, in order to detect and analyze physical and mechanical characteristics of the components used in serial production (such as, for example, DSC curve and IR Spectrum Analysis).